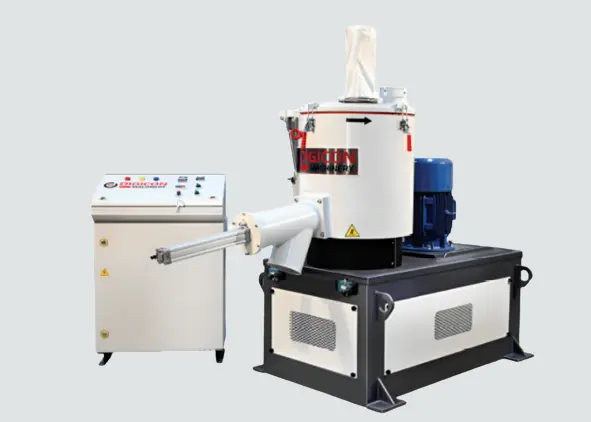

HIGH SPEED MIXER WITH PNEUMATIC CONVEYOR

Digicon Offers High Speed Heater Cooler Mixer with Pneumatic Conveying System to transport bulk materials. It is very smooth, Dust Free and speedy process for transporting materials from Ground Hopper to Batch Hopper.

- A compact dust free close loop system.

- Total Batch transport from Ground Hopper to Batch Hopper or Silo.

- Highly consistency in conveying bulk materials.

- No Rotating Part is in contact with raw materials.

- Increases efficiency of Mixer.