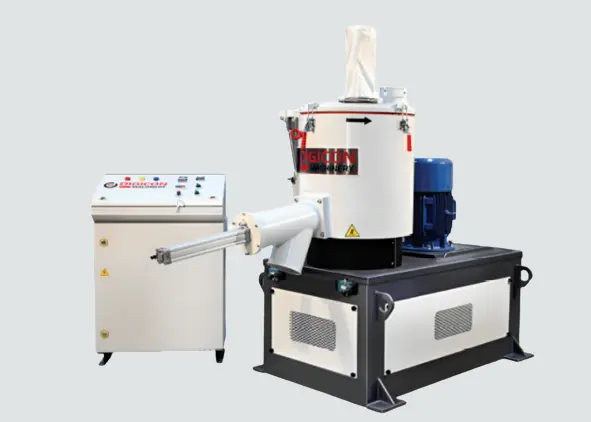

HIGH SPEED HEATER COOLER MIXER WITH SPIRAL CONVEYOR

In High Speed Heater Cooler Mixer heat is generated by

friction.

Mixing Tools are rotating at high speed and due to friction,

heat is generated & hence it is known as Heater Mixer. The

Material either solid, liquid or any pasty components inside

heater chamber is properly heated within a specific time. The

hot materials should be cooled subsequently in Cooling Chamber

which is known as Cooler mixer.

The material from heating chamber is fed into cooling chamber

to cool down at desire temperature. After cooling, the

compounds are ready in free flow condition for further

process.

SALIENT FEATURES OF HEATER COOLER MIXER

- Stainless Steel Vessels with mirror polished surface inside the vessel.

- Robust Design of machine to keep it vibration free.

- Double jacketed Heater and Cooler vessels to avoid heat loss.

- Special design of mixing tools with TC coating edge.

- Fast discharging of compounds by pneumatically operated valve.

- Pneuma Seal design prevents infiltration of powder in bearings.

- Lid is made up of high quality aluminium or SS and it is pneumatically operated.

- Cooling ring inside cooler is to enhance cooling capacity of cooler mixer.

- Optimum design of cooling surface area in Cooler Mixer.

- Minimum down time for repair and maintenance.

- Self Cleaning, quick and easy fitting of parts.

| Sr. No. | Model No. | Batch Capacity in Kg/Batch | Drive in DHM (kW) | Drive in DCM (kW) |

| 01 | DHM 50 - DCM 150 | 15 | 7.5 | 1.5 |

| 02 | DHM 130 - DCM 400 | 40 | 15 | 3.7 |

| 03 | DHM 200 - DCM 400 | 70 | 30 | 3.7 |

| 04 | DHM 250 - DCM 600 | 90 | 37 | 5 |

| 05 | DHM 350 - DCM 1000 | 120 | 55 | 7.5 |

| 06 | DHM 500 - DCM 1500 | 200 | 110 | 15 |

| 07 | DHM 750 - DCM 2000 | 300 | 132 | 18.5 |

| 08 | DHM 1000 - DCM 2500 | 400 | 200 | 30 |